Creators,

There is one woodworking piece of mine that I think I have not given enough exposure. Do to the fact that it is the most functional piece I have made and that it is a piece that I constantly use, I am sad to say that ironically I have not given it enough acknowledgement.

This piece has an interesting history and a history that I hope will last longer then I. As of now it is a piece in need of repairs do to this history.

This piece is my workbench. An 18th century Roubo inspired workbench. Very non-traditional with its natural edges, two square corners, tripod style legs and single stretcher, it is at times unfriendly with its functionality and a quark to see and use.

It has weathered my blood, sweat and tears. At times has waited patently for me to use and has held me up for short naps late nights at school in the past. It also has secrets here and there that it keeps for me. I have lovely memories being covered in dust beside my bench with lust and trust, at school working waiting to find the perfect moment to confess my love to a girl of my dreams. But that's another story.

As said before do to its history and design it is in need of rework, which is why this bench will now exist and have its rebirth in cyberspace

The story started back when I was in college and a new student to wood exploration. In need of wanting to work on a piece exclusively in hand tools and in want of building something that would last me a lifetime, and be functional though out that time, I decide to make a Roubo workbench.

A Very Very Brief History of the Roubo

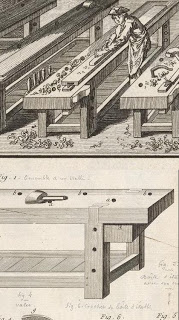

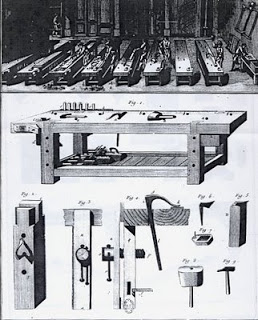

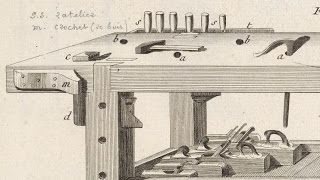

André Jacob Roubo was a French cabinetmaker and author. The son and grandson of Master Cabinetmakers, he earned that designation in 1774 through the publication of his masterwork treatise on woodworking. In his publication, in wish I can only presently wish to own, he wrote of a jointers work bench, design and specifications. This Roubo Workbench was a beefy one. Here are some pictures of this 18th century monster.

The top made of a thick solid slab and with very archaic (but fast and functional to the skilled) clamping devices it is a design not very reasonable in the modern world. This appealed to my impractical nature. Now only realizing an impactical nature that is much more practical then I was aware of since there is a revival of the Roubo workbench among wood workers.

Most modern work benches have tops that are laminated from very stable quarter sawn pieces. This is because one can create a laminated top with greater ease and with more reliability than try to find a massive hardwood tree cut a stable piece of this tree and make a top. This would be laborious, expensive and the wood will move (lose its squareness) in the years it would take for it to dry.

The Giants Felling

One very wet and windy winter in 2007,,,,I think, an Iron Bark Eucalyptus fell which was located in the parking lot of my university, Cal State University, Long Beach. Our department was in luck! The luck was two fold, lucky the school was not in session, no cars or delicate little humans to smash for this tree was at least 4 stories high and at least 4-5 ft across that’s just the trunk (the Iron Bark is a very dense and hard wood, when dry!).

There were limbs everywhere. We were also lucky that we owned a portable bandsaw mill. That winter day we spent most of it milling the trunk and bigger limbs to sizable slabs so we could put them in our pick-up trucks and haul them back to the shop. The interesting and dangerous character of the Iron bark is that it is a very high growing tree that is brittle due to the weaving of the fibers and density. This particular tree seemed to have been rotting in the roots. One strong wind and it gave.

The scene was just awe provoking. The tree literally fell broke and bleed. As we moved the pieces around and stood some up water ran out in streams creating pools of clear blood. It was a very curious and eye opening experience. The, smell fantastic. A fallen giant in our Urban Forrest.

|

| Fred Rose working the Mizer. |

One trip with just a fraction of the tree in my truck made it bottom out. I estimate one trip was one ton plus.

My Roubo (the Sun Bear)

The pieces probably stayed in the stacks to dry for bout a half a year to a year. At this time I decided to make my bench with not so thoroughly dried wood. I knew in time the bench would move. And will always do to temperature and moister change.

I will not bore you with the design aspects of the bench they are personal and always in flux, but the making is something to be mentioned. The only time I used woodworking machinery on this piece was in the milling of the top and the milling of the apron and legs. For the leg vise I did use a router jig to make the wooden screw. I squared the top, chopped the tendons and mortises using traditional hand tools. It was and is a very laborious thing and I love it. Oh yes and no glue was used. Makes future repairs and mods easy.

So the present day:

As I said before the wood was still wet as I worked on the bench. Now the top is warped partly do to its drying/movement and a bad fox joint (I will explain what that is later).

The first step in the rebirth is the re-design of the third leg. The fox joint is a tenon joint that wedges when hammered in, creating a once square tenon into a wedge preventing it from it ever coming apart. The fox joint I created was ill in execution.

I had some thoughts about making a dovetail joint to attach the leg but first I must fill in the mortise that was previously there and create a square area to attach the leg. I will square the area to the other two legs as much as possible since I am dealing with a piece of wood that is not square to begin with. The essential squaring that will be need for it to function will come later. In dealing with this piece everything is relative: squareness, levelness and all. This does not mean it will not be perfect for its function. There is too much emphasis on perfection in this world. Perfection is relative.

Here are some vids showing the old fox joint mortises, the leveled area to fill and the old tenons and third leg.

My Roubo still needs hardware, dogs, and other various things that will make it a solid work bench and an odd thing to see.

The next update will be the making of the plug and the design of the new joint. Dovetail, twin tenon, or something absurdly inconvenient?

Until next time,

-DBL

Tweet