My Fellow Americans and Terrestrials,

Yes, last Tuesday I

did not post a Tuesday post. I

have no excuse except fatigue. I

got home and just could not resist the warm soft nest in my room. I owe you twice the words this

Tuesday. Until then I present to

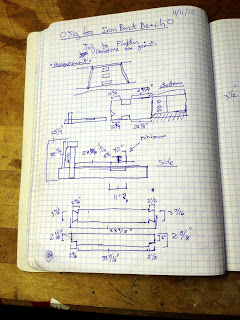

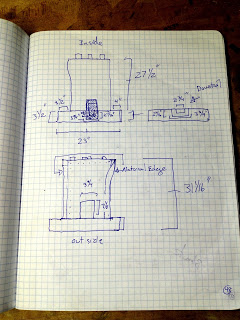

you the second stage of a long and over do project. My Roubo inspired Workbench (The Sun Bear).

-DBL

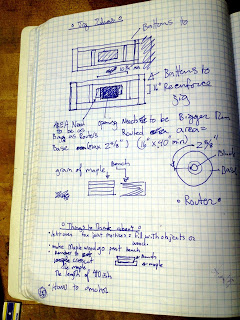

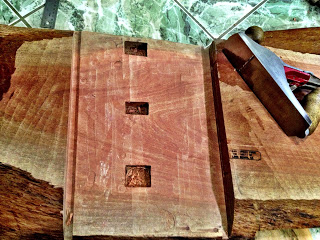

Jig and Router

Originally I had

intended to level out the area where the faulty fox joint mortises currently

exist using only my able body and bench planes. Well for sake of speed and a newer experience I

decided to finally purchase my first Porter Cable 1 ½ hp router.

I had started to

level the area using hand tools and left it at a good place for the router to

do the rest of the dirty work, but still not be bog down by too much material

removal. Iron bark is dense and

splintery and can wear down tools, but can also be machined pretty nicely. Almost as nicely as its cousin the

lemon scented eucalyptus.

One of the troubles

I am dealing with in this project is the wind (pronounced whined) that exists

in the top of the bench. The pair

of legs on the left side are pretty leveled. The problem is at the other end. A wind in a board is a twist in which each end of the

board is at different axis.

|

| Full view of jig |

|

| New unused Porter Cable router |

|

| Battens |

|

| Anchored at the base of the legs |

|

| In retrospect this area should of had more battens |

|

| Hand worked unroutered |

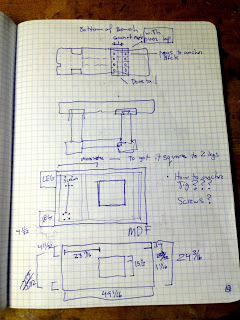

After the jig was

built what was left to resolve was how to routering the middle of the area that

was being removed. Since the base

of the router has a radius of 2 5/8 in. I had to add a movable supporting sled

in the middle of the jig. As I

worked closer to the center I readjusted the sled.

|

| Support sled |

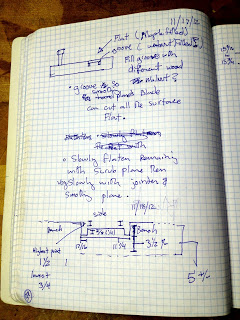

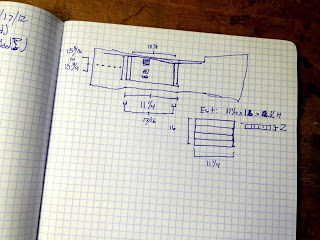

When I had the

majority of the area routed I decided to remove the jig and do the rest of

the finesse work using hand tools.

Hopefully I have a good flat reference to finish flattening it with out

too much grief.

*A side note. The grooves I have left on each side of the flatten area will help my squaring of the top. To do this I will use my Jointer plane. Some bench plane blade's do not extend to the edge of the body. This groove will correct for the area that the edge of the jointer plane can not reach. I will later fill this area with a contrasting wood or an exotic wood for a nice adhoc detail.

|

| Scrub plane for the rest of the hogging out |

|

| After using the scrub plane |

|

| Rounded corners |

|

| Cleaned up area where the router missed |

That is the stage

the Sun Bear remains. Until the

next time be safe and love what you do.

Oh speaking of. When woodworking, using heavy equipment, power tools, sharp tools or when you just want

to do something right listen to your body and mind and the spirit will follow. When one of them is ready to quit, take a break. Remember this is fun, not work. I forget this often and this time I got

a gentle reminder. Just when I was

about to quit, just when I felt myself rushing, I told myself "ok time to quit". My mind did but my body followed through…

sliced my hand with my recently 1000 grit sharpened paring chisel. Luckily I was doing very light work, but

the tool had a very keen edge.

|

| Mental/ Physical Fatigue + Sharp Tools = Two Stitches |